I’ve got an electronic door lock that I control via my Insteon system to lock when I leave the house, and even monitor whether the deadbolt is set or not. But over the winter, I found that the lock was getting a little tight to turn and sometimes failed when automatically trying to lock or unlock. It turns out this stickiness was due to the door settling a tiny bit and the bolt was rubbing on the strike plate.

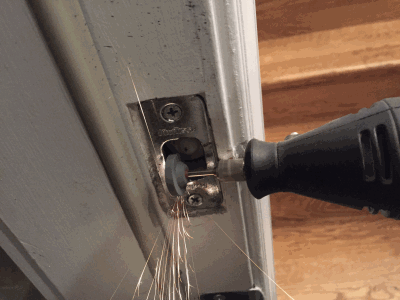

I considered removing the plate, sealing the existing screw holes with some wood epoxy, and remounting the strike plate 1 millimeter lower to eliminate the friction and allow the bolt to slide more easily. Instead, I realized an easier solution: just increase the size of the strike plate hole. After looking closely into the gap between the door and frame and seeing that bolt was rubbing on the bottom side of the hole, I confirmed that the door was indeed sagging by pulling straight up on the knob while throwing the bolt. Sure enough, it slid in and out without any resistance. So, I simply used the metal grinding attachment on my rotary tool to file a millimeter or so off the bottom of the strike plate. Viola! Problem solved.

Of course, this tip is more useful if you’ve got an electric lock where the extra force required can cause problems, and I wouldn’t suggest it if the bolt is SO far out of alignment that it doesn’t go in at all, but it’s a quick and easy fix for a minor adjustment. Speaking of electronic locks, though: just remember that with great power comes great responsibility.